This process transfers all items accumulated in WIP to Cost of Sales for the project. It includes generating the customer invoice and recognizing revenue and costs. The process is for normal invoicing. Deposit invoices are discussed elsewhere.

Start the process when you receive the signed packing list (delivery ticket).

Generate an invoice and recognize revenue

● Generate invoices

● Review/Consolidate invoices

● Print invoices

● Update invoices

Match costs to revenue

● Clear Cost WIP

● Update Cost WIP

Close a project

● Close projects

● Update

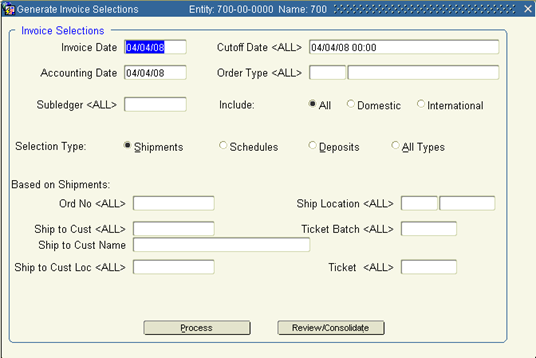

1. From the Main Menu, go to Distribution/ Order Entry/ Processing/ Invoicing/ Generate Invoices.

2. The fields on this screen are grouped in three sections. Fill in the fields as indicated:

A. Invoice Selections

Invoice Date |

Leave the default, which is the current date. The Invoice Date on the Review/Consolidate screen overrides this date. |

Accounting Date |

Leave the default, which is the current date. The Accounting Date on the Review/Consolidate screen overrides this date. |

Subledger |

Leave blank for “all”. |

Cutoff Date |

Leave the default for Shipment based invoices. For Milestone invoicing based on scheduled dates, enter the cutoff date you want to capture scheduled invoices up to. |

Order Type |

Leave blank for “all”. |

Include |

Select the All button. |

B. Selection Type

Shipments |

Select Shipments for invoicing Orders that have been shipped and invoice based on Order Lines. |

Schedules |

Select Schedules for invoicing Milestone (OES) invoices. |

Deposits |

Select Deposits to invoice Deposits defined on Order Deposit screen. |

All Types |

Select to invoice all three selection types. |

C. Based on Shipments

Order No |

The order for which to generate invoices. The system may be set to require this field for processing in your Company Control record. If this is not set, other fields below may be used to select invoices. |

Customer Cust Loc Ship Location Ticket Batch Ticket |

Leave Order blank and select based on Customer |

3. Click Process to generate invoice data based on the criteria specified in selecting orders to invoice.

The system will prompt you that it is generating the invoice. Click OK.

Repeat steps 1 – 3 for each project order to be invoiced.

Invoice multiple project orders - examples

Where do you invoice a project order?

Should you invoice after the last project order is installed?

Consider a project with three orders tied to it. All the orders are placed in January. Order 1 is shipped in January, Order 2 is shipped in February, and Order 3 is shipped in March. Should the project invoice be generated in March? Can it be generated in January?

In this circumstance, you would consolidate the order after all products have shipped. You may create a milestone code for these orders. Then consolidate the invoice. You can manage this based on scheduled invoicing. Generate the invoice in January (for all orders) and then ship products as they arrive. Remember, this is a process that must be managed by the user. It can be date-driven automatically (i.e., end of January invoice 100% and end of March invoice for Revenue Recognition - system only transaction).

Another method is to generate an invoice for each order after it ships. Each invoice would be charged to the same project. In the example of three project orders that were ordered at the same time but shipped separately, you can either send an invoice as the products ship or consolidate them into one invoice after all are shipped.

In either case, the amounts recorded to the project are the same. If you want just one invoice before the orders ship, then the Milestone Invoicing option would be the best choice.

Invoice your customer prior to receiving a vendor invoice

You may invoice a customer at the time the service is rendered but before you receive the invoice from the vendor. (The PO must be received first.) If you are invoicing an outsourced service, the system moves these dollars to WIP and accrues the purchase until the vendor invoice arrives.

You may invoice the customer independent of the vendor invoicing. The system will properly account for cost or WIP until the point of vendor payments. It will manage any discrepancies at that time automatically.